- Ammonia, Engineering, Industrial Refrigeration, Waikato

DESIGN & BUILD REFURBISHED PLANTROOM

PROJECT HIGHLIGHTS

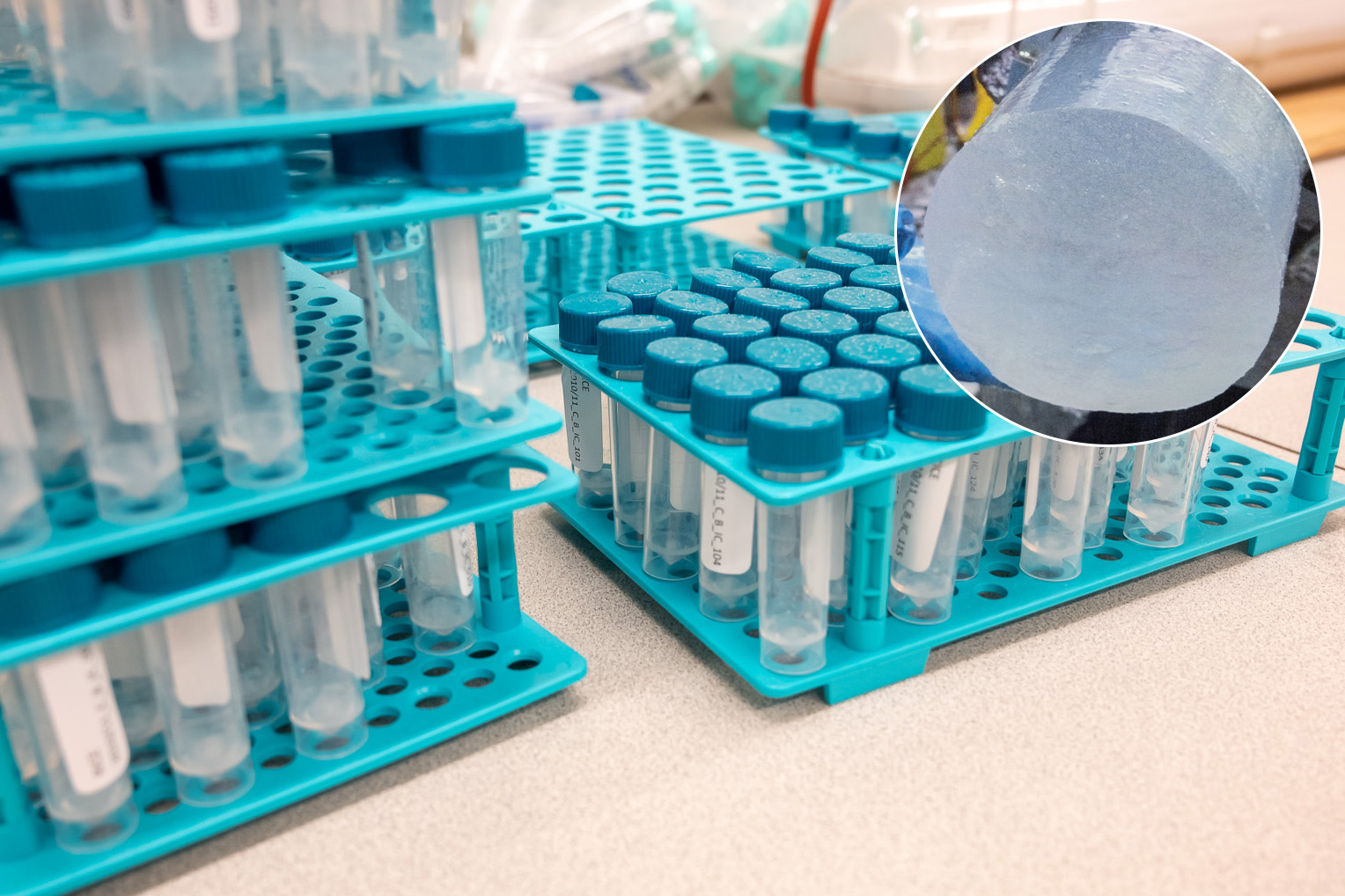

- Replaced all compressors, piping, and evaporative condenser

- Complete electrical upgrade including rewiring of the entire plantroom and new PLC

- Refrigeration capacity of 1.4MW at -10˚C to service 10 coolstores

- Built and commissioned in only 12 weeks

This client came to us with concerns about insufficient cooling capacity and performance issues with their existing ~30-year-old plant. Excel Engineering were engaged to deliver a turnkey, design & build refurbished plantroom to meet their operational goals.

The upgraded plantroom features new compressor units, an evaporative condenser, and MCC room; providing

1.4MW of cooling at -10˚C to service 10 coolstores.

- Design: Led the detailed process, mechanical & piping, and electrical & automation design

- Equipment: Selected & supplied equipment including compressors, valves, pumps, VSDs and evaporative condenser

- Build & Commission: Installed & commissioned all equipment, piping, and MCC room

- Project management: Throughout the design, procurement, build and commissioning phases

Impact & Benefits:

- Greater cooling capacity to meet operational requirements

- Improved reliability with full N+1 compressor redundancy system

- Modern control system with variable speed drives resulting in more stable coldstore temperatures.

Excel Engineering successfully built and commissioned this refurbished plantroom in just 12 weeks. This rapid turnaround is a testament to our team’s expertise and ability to perform under pressure.