- Ammonia, Engineering, Industrial Refrigeration

Design & Build New Energy Centre

PROJECT HIGHLIGHTS

- 7 MW+ of hot water at 65°C from two integrated chiller-heat pumps

- 15 MWr of chilled water at 3°C from three chilled water skids and the heat pumps

- New water reticulation system providing process cooling for the entire site

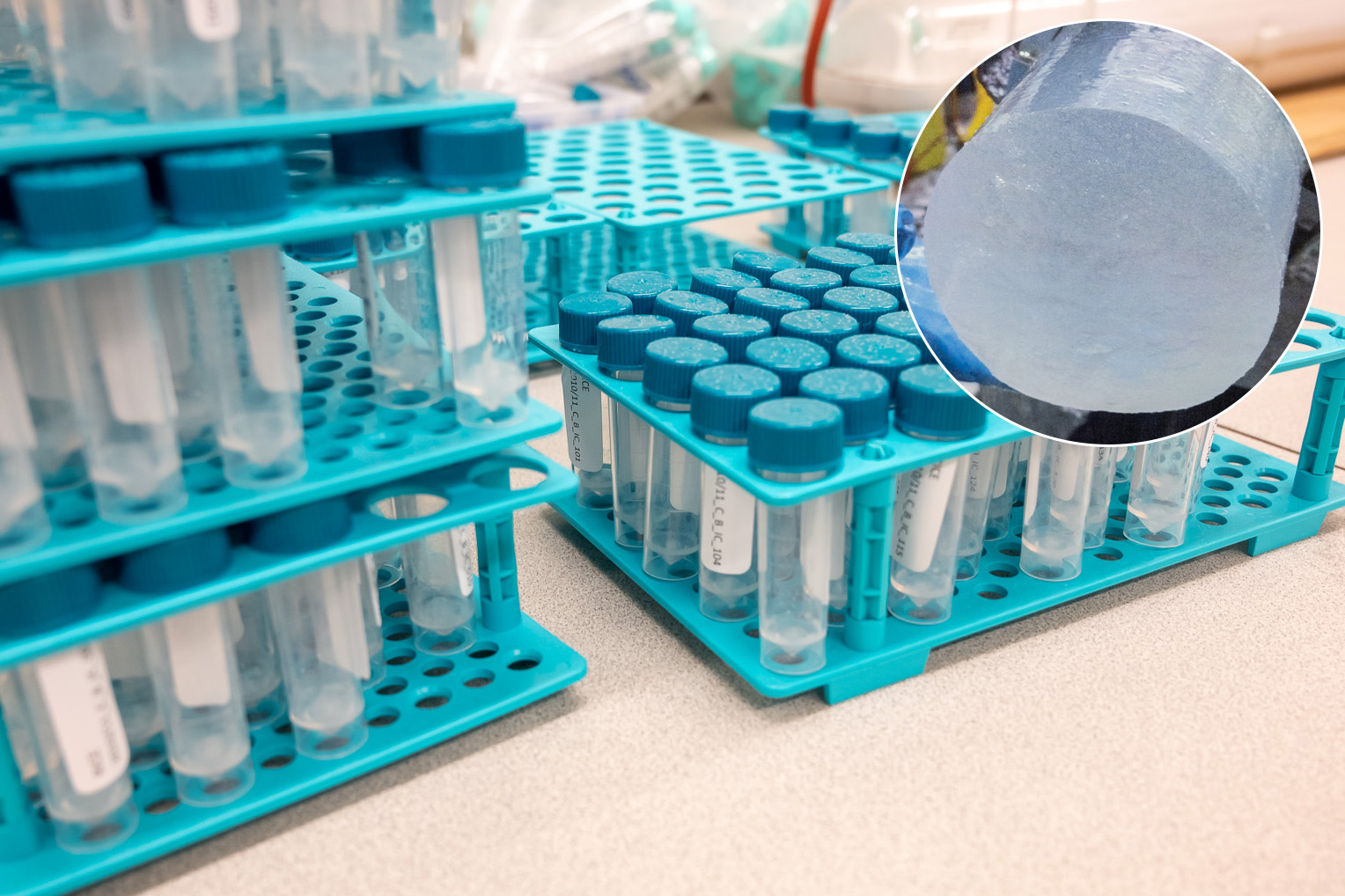

- Reduced ammonia charge on site by over 20 metric tonnes

- Design and build including electrical, automation, pumps and pipework

Excel Engineering is proud to be part of the largest industrial heat pump project in Aotearoa New Zealand.

We successfully designed, installed, and commissioned a high-efficiency heat pump system. This initiative aimed to enhance energy efficiency and sustainability by reclaiming heat from chilled water production to supply hot water needs.

The project featured two heat pumps, each contributing to a 7 MW+ heat load, alongside three chilled water skids producing 15 MWr of chilled water at 3°C.

- Mechanical, Process, and Electrical Design: Ensuring optimal integration of the heat pumps with the existing factory systems

- Automation and Control Systems: Implementing smart control solutions for efficient operation

- Pumps and Pipework Installation: Configuring a robust circulation system to maximise energy recovery

- Heat Pump Skid: Installation and commissioning

- Chilled Water Skids: Installation and commissioning

Impact & Benefits:

- Enhanced energy efficiency through heat reclamation from chilled water production

- Significant reduction in fossil fuel dependence for hot water generation

- Increased reliability and operational efficiency for their hot water system

- Significant reduction in ammonia volume on site, improving overall site safety

- Sustainable infrastructure supporting the client’s decarbonization strategy

Excel Engineering’s successful project execution demonstrates its leadership in delivering advanced, energy-efficient heating and cooling solutions for large-scale industrial applications.